Author: Ali Kosari Mehr

Sedimentation

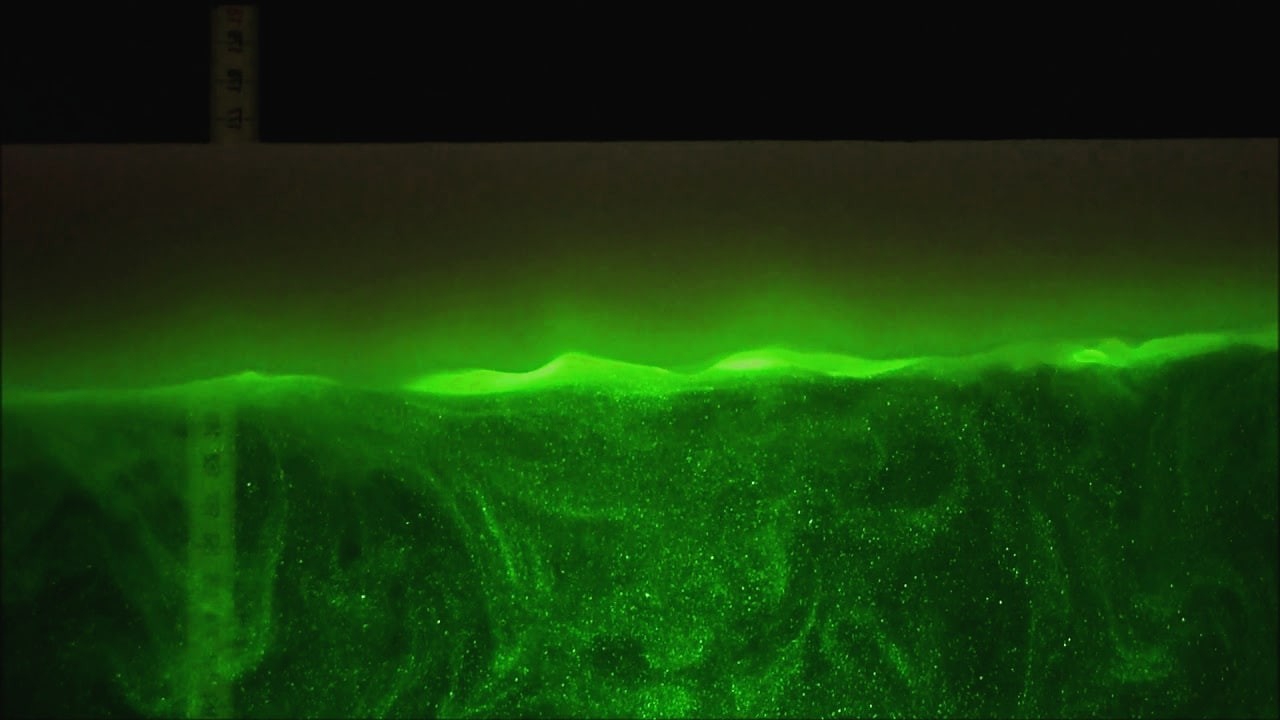

Sedimentation is a thick-film deposition process in the simplest form of which a substrate positioned at the bottom of a container is coated by natural sedimentation. It is worth mentioning that this process is undesirable in many thick-film deposition processes and that attempts are made to prevent it. The method’s thickness capability, ink viscosity range, and powder loading are 1-50 μm, <0.01 Pa-s, and <0.01 vol%, respectively. The rationale behind the utilization of a low-concentration powder suspension in this process is that the particles could be deposited in a controlled manner, resulting in a higher degree of control over the thickness of films. In this method, the deposition rate can be increased by means of a centrifuge process; while the deposition rate is proportional to the gravitational acceleration in gravitational sedimentation, it is proportional to the centrifugal force’s radius multiplied by the square of the centrifuge’s angular velocity in the centrifuge-assisted sedimentation. Accordingly, a centrifuge-assisted system can increase the deposition rate to higher orders of magnitude in comparison with gravitational sedimentation. Having undergone the centrifuge process, the sample is removed from the container before it can be dried/processed, culminating in the creation of a high-density green-body film.

References:

- Dorey R (2012) Thick-film deposition techniques: How to make thick films – the processing techniques used to create films. Ceram Thick Film MEMS Microdevices 63–83. Webpage

-

20 Aug, 2022What is Auger electron spectroscopy?

20 Aug, 2022What is Auger electron spectroscopy? -

13 Jul, 2022Classification of vacuum pumps

13 Jul, 2022Classification of vacuum pumps