Author: Ali Kosari Mehr

Ion plating

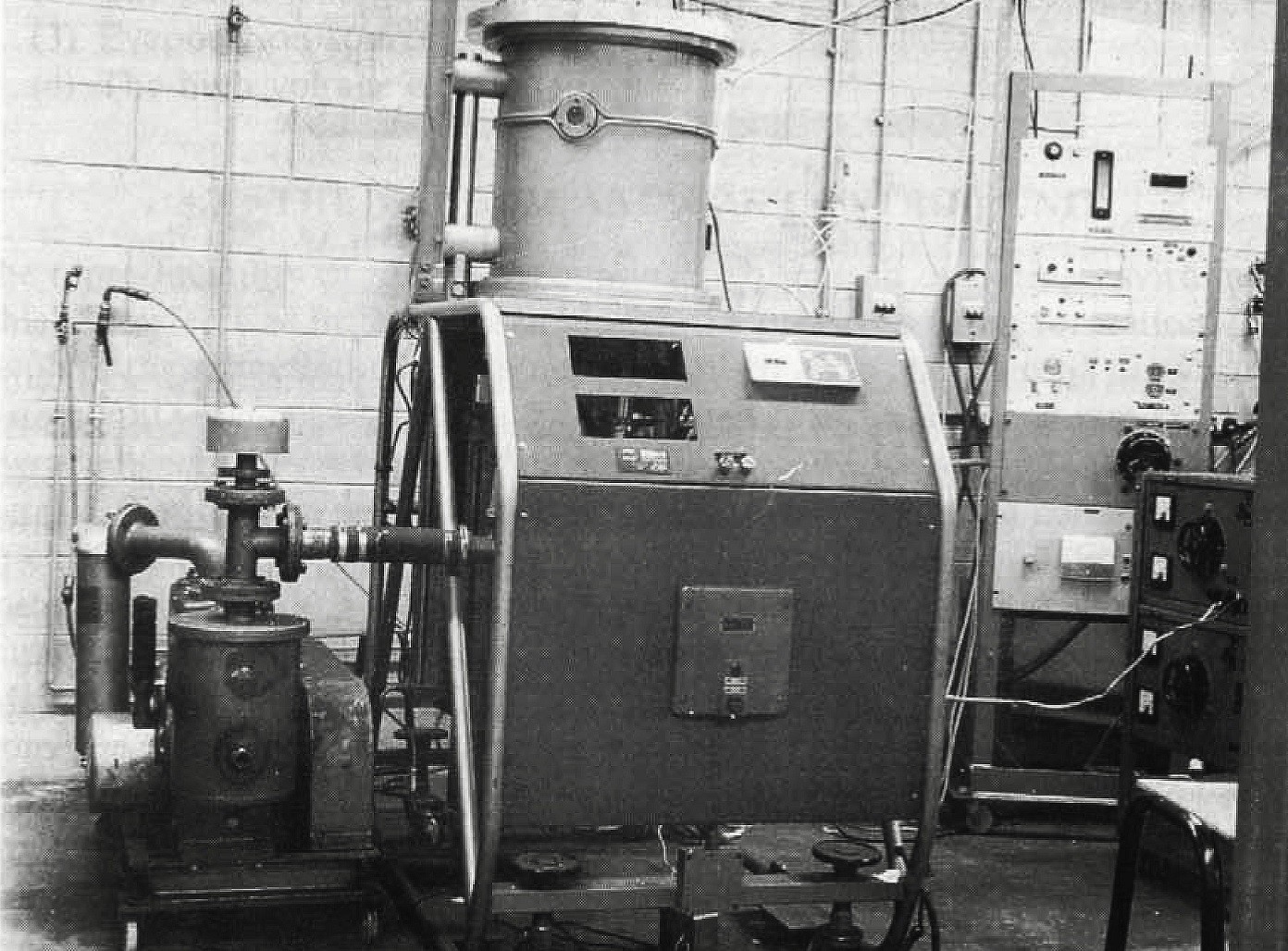

Proposed by Donald M. Mattox in the early 1960s, ion plating is a vacuum-based deposition method using either thermal evaporation, electron beam evaporation, cathodic arc evaporation, sputtering, or chemical vapor precursor as the deposition source. In this method, the characteristics of a growing film (e.g., adhesion, density, morphology, index of refraction, residual stress, etc.) can be modified by means of inert/reactive particles bombarding the surface of the film in a continuous/periodic manner. Accordingly, the bombardment can occur through two means: plasma-based ion plating and vacuum-based ion plating. In the former case, ions are accelerated towards the substrate via plasma generated in the deposition chamber. In the latter case, ions are generated by an ion source. Ion plating is mainly comprised of three phases: surface preparation, nucleation and interface formation, and film growth.

In the surface preparation phase, contamination at the substrate surface is largely eliminated by sputter cleaning. In this connection, sputter cleaning in the ion plating method is an inseparable part of the process, proceeding during deposition. Hence, the cleaning prevents recontamination of the substrate during growth; however, this can cause gas atoms to be trapped in the growing film. Therefore, the impact of the mentioned problem can be alleviated by heating the substrate during deposition. In addition, the bombardment of the surface can lead to the production of lattice defects; these defects can be particularly problematic for semiconductor processing since they can serve as electron traps in the vicinity of the interface. Furthermore, it is noteworthy that the nucleation density of a surface being bombarded is higher compared to that of a surface not being bombarded, owing to various factors such as having a clean surface, defects in the surface, surface heating, and recoil implantation [1,2].

References:

-

20 Aug, 2022What is Auger electron spectroscopy?

20 Aug, 2022What is Auger electron spectroscopy? -

13 Jul, 2022Classification of vacuum pumps

13 Jul, 2022Classification of vacuum pumps