Author: Ali Kosari Mehr

Electrodeposition

Electrodeposition is a deposition method of thin/thick films with three subcategories:

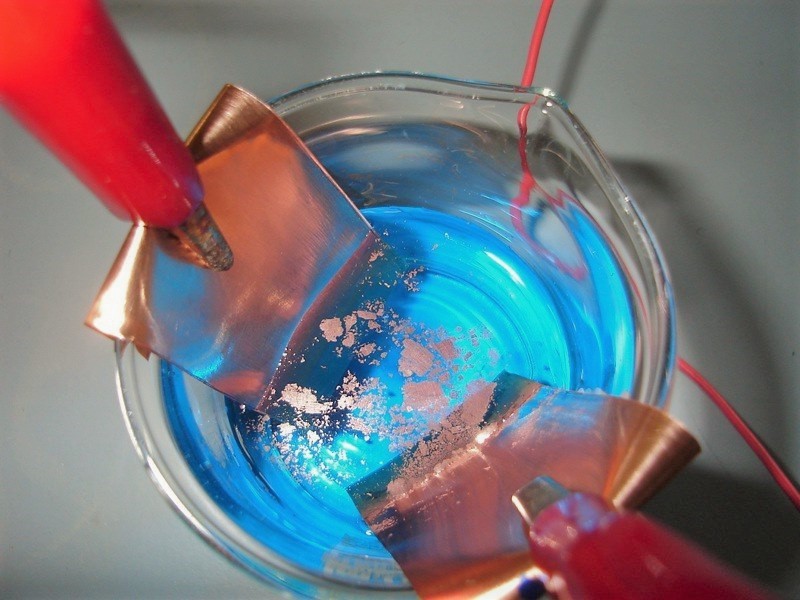

1- Electroplating: With the mechanism being based on the reduction of cations (i.e., cations obtaining electrons), this method is widely utilized for the deposition of alloy and metal thin films. In this method, the reduction process in the electrolyte of the salt containing the given metal occurs by means of providing external current. Moreover, the sites where anodic and cathodic reactions happen are separate, thus resulting in the substrates having to be conductive. Illustrating the advantages of electroplating, one can refer to the ability to control the thickness of films with the precision of a fraction of a micron. However, as it was noted, the substrate must be conductive, and the environmental pollution is significant owing to the special electroplating bath. In addition, the fundamental laws of the electroplating process are governed by Faraday's second law:

a) The weight of the deposited metal is proportionate to the quantity of the passed electricity.

b) With the quantity of the passed electricity being the same, the weight of the deposited metal is proportionate to its electrochemical equivalent [1–5].

2- Electrophoretic deposition (EPD): Being low-cost and simple, this method is considered to be a film deposition method the main advantage of which is the short time required for the formation of films. Accordingly, this method in which an electrostatically stabilized suspension is utilized is comprised of the electrophoresis process (i.e., the movement of charged particles in a suspension under the impact of an electric field) and the deposition process (i.e., the coagulation of particles into a dense mass). With an electric field being applied, the EPD process occurs through the migration to an electrode of charged particles dispersed in a suitable liquid. As it was mentioned, the deposition of films on the electrode happens through the coagulation of particles. In other words, electrophoretic migration leads to the accumulation of particles and deposition of a homogeneous layer on the given electrode [6, 7].

3- Underpotential deposition (UPD): The deposition of metallic sub-monolayers or metallic monolayers (or at the most bilayers) on a surface with the potentials being more positive than those predicted by the Nernst equation is called underpotential deposition. Accordingly, the deposition of a metallic film on a metal surface at underpotential can culminate in the preparation and the design of surfaces having a variety of applications; for instance, production of compound semiconductors, electrocatalysis, design of biosensors, etc. [8].

References:

- Schlesinger M, Paunovic M (2011) Modern Electroplating: Fifth Edition. John Wiley and Sons Webpage

- Boyner J (1986) Electroplating (Workshop Practice Series). Trans-Atlantic Publications Webpage

- Basile A, Tong J, Millet P (2013) Inorganic membrane reactors for hydrogen production: An overview with particular emphasis on dense metallic membrane materials. In: Handbook of Membrane Reactors. Elsevier Inc., pp 42–148 Webpage

- Sebayang D, Hasan SBH (2012) Electroplating. InTech Webpage

- Kanani N (2005) Electroplating: Basic Principles, Processes and Practice. Elsevier Ltd Webpage

- Sarkar P, Sakaguchi S, Yonehara E, et al (1997) Electrophoretic Forming of Functionally-Graded Barium/Strontium Titanate Ceramics. In: Functionally Graded Materials 1996. Elsevier, pp 221–226 Webpage

- Kiwi-Minsker L, Renken A (2005) Microstructured reactors for catalytic reactions. Catal Today 110:2–14. Webpage

- Oviedo OA, Reinaudi L, Garcia S, Leiva EPM (2016) Underpotential Deposition From Fundamentals and Theory to Applications at the Nanoscale. Springer International Publishing Webpage

-

20 Aug, 2022What is Auger electron spectroscopy?

20 Aug, 2022What is Auger electron spectroscopy? -

13 Jul, 2022Classification of vacuum pumps

13 Jul, 2022Classification of vacuum pumps