Author: Ali Kosari Mehr

Cathodic arc evaporation (CAD or CAE)

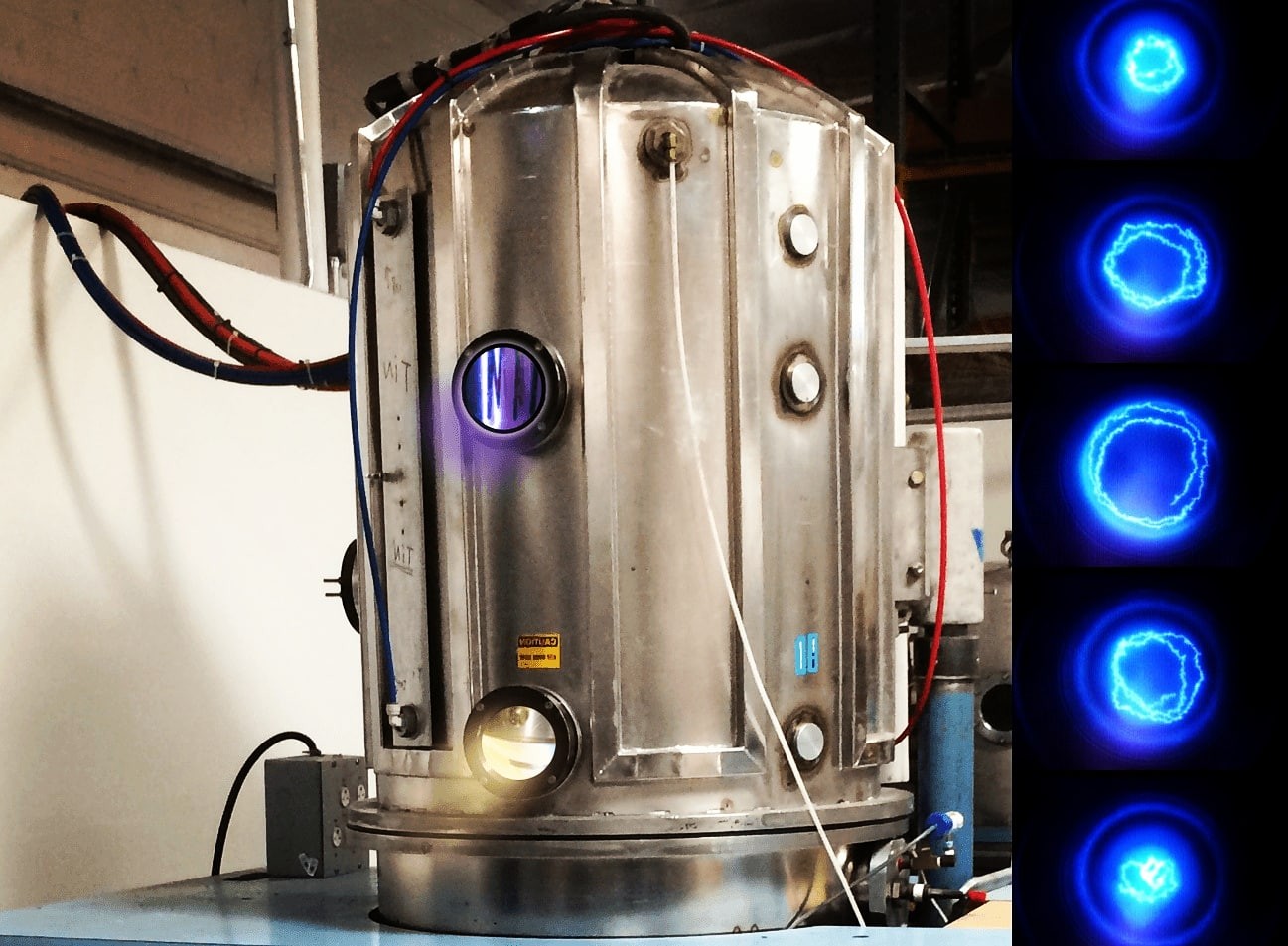

Cathodic arc evaporation (CAD or CAE) is a thin-film deposition method in which a low-voltage, high-current arc generated between an electrode and a cathodic target, being a conductor, culminates in the evaporation from the cathodic surface, and as a result, the deposition of films. Given that the impingement area of the arc on the target surface is small, as the direct result of the small cross-sectional area of the arc, the local temperature can reach very high values, up to about 15000°C. Therefore, being highly ionized, the material evaporated leaves the target’s surface with very high energies. Furthermore, the impingement area on the target surface changes in a seemingly random manner; however, now and then, a magnetic system is utilized in this connection to change the area in a regular raster scan.

Although the employment of cathodic arc evaporation technique has been reported to yield notable results in some cases (e.g., the refractive index of 2.735 for TiO2 at 633nm), it is successfully utilized as a means of coatings cutting tools in general. Moreover, provided that molten droplets ejected by a simple cathodic arc reached growing films, they would pose grave problems for optical applications by means of acting as scattering defects. To rectify the problem for optical applications, technologists have used a magnetic filter whereby the evaporated material having a charged nature can be magnetically directed to be separated from undesirable particles. It is noteworthy that ion bombardment can also be added to this process – i.e., ion-assisted filtered cathodic arc evaporation (IFCAD).

References:

- Angus Macleod H (2018) Recent developments in deposition techniques for optical thin films and coatings. In: Optical Thin Films and Coatings: From Materials to Applications. Elsevier, pp 3–23 Webpage

-

20 Aug, 2022What is Auger electron spectroscopy?

20 Aug, 2022What is Auger electron spectroscopy? -

13 Jul, 2022Classification of vacuum pumps

13 Jul, 2022Classification of vacuum pumps