Author: Ali Kosari Mehr

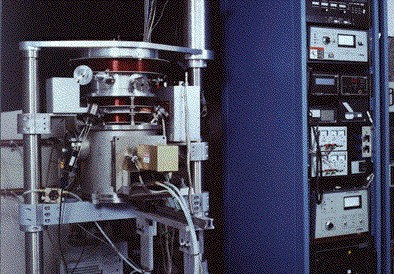

Activated reactive evaporation

Proposed by Bunshah, activated reactive evaporation (ARE) is a thin-film deposition method employed for depositing oxides, nitrides, and carbides of metals. In the ARE process, the evaporation of alloys/metals occurs with the plasma of a reactive gas being present. Illustrating this process, one can mention that TiC and TiN films can be grown by means of evaporation of titanium in the presence of C2H2 and N2. Hence, the main role of the plasma is to cause the reactions essential for the formation of compound material and to adjust the kinetics of the growth – accordingly the structure and morphology of films.

In the ARE method, the evaporation process occurs via a thermal source such as cathodic arc and electron beam. Not being mainly dependent upon the plasma, the rate of evaporation increases with the increase in the temperature of the target surface and the vapor pressure of the target material; thus, the evaporation rate of the ARE process is largely independent of the plasma.

In the ARE process, the interaction of the thermal source with the plasma does not cause any acute problem for the deposition rate of the compound layers. Accordingly, the compounds formed on the surface of the metallic target are probably dissociated owing to the extreme temperature at the target area, especially with cathodic arc or electron beam being used as the thermal source.

Given that diverse reactions can occur by the interaction of the evaporated material and the plasma, only some reactions are of significance in the ARE process, namely electron-impact dissociation, ionization, and excitation. Furthermore, it is common knowledge that the presence of a glow discharge leads to the bombardment of the substrate by electrons, ions, and neutrals; the process parameters and geometrical position of the substrate in the system are the factors deciding the energy and nature of the species bombarding. Hence, exerting a considerable impact, the bombardment can cause changes in surface chemistry of the substrate, elevation of substrate temperature, re-sputtering of the deposits, the incorporation of gas in the film, and the modification of grain size, morphology, crystal orientation, etc. [1-3].

References:

- Deshpandey C V., Bunshah RF (2008) Activated reactive evaporation—A review. 33:33–48. Webpage

- Bunshah RF, Raghuram AC (1972) Activated Reactive Evaporation Process for High Rate Deposition of Compounds. J Vac Sci Technol 9:1385–1388. Webpage

- Wasa K, Kitabatake M, Adachi H (2004) Thin Film Processes. In: Thin Film Materials Technology. Elsevier, pp 17–69 Webpage

-

20 Aug, 2022What is Auger electron spectroscopy?

20 Aug, 2022What is Auger electron spectroscopy? -

13 Jul, 2022Classification of vacuum pumps

13 Jul, 2022Classification of vacuum pumps